Innovative Solutions for Optimal Hydraulic Performance

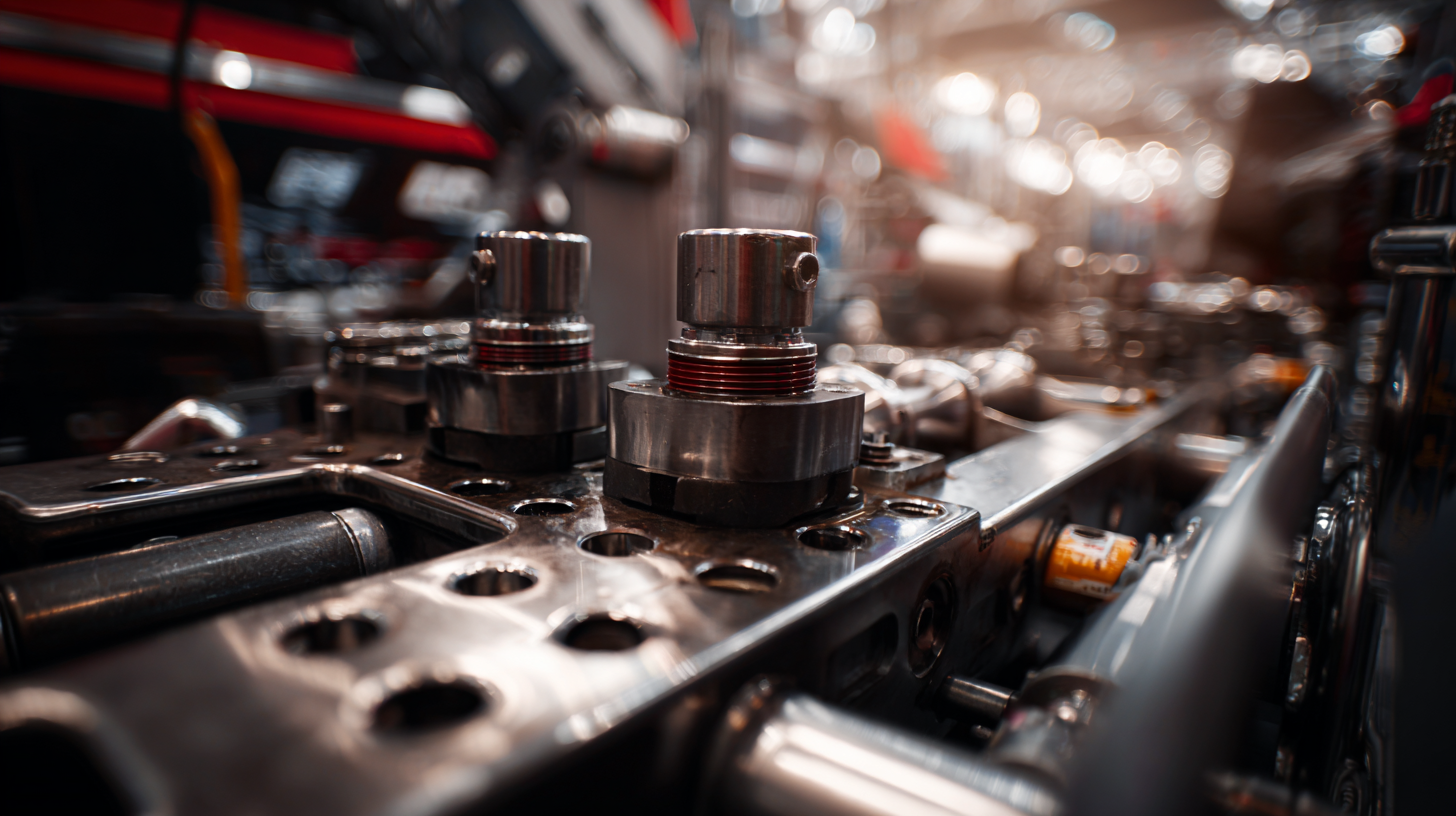

In the ever-evolving landscape of industrial technology, the quest for optimal hydraulic performance has never been more critical. As we look towards the horizon of 2025, emerging trends in hydraulic solutions promise to revolutionize the way we approach fluid power systems across various sectors, from manufacturing to renewable energy. This blog will explore innovative strategies and cutting-edge technologies that enhance hydraulic efficiency, reduce energy consumption, and improve system reliability. By examining key advancements and providing actionable insights, we aim to equip industry professionals with the knowledge needed to implement effective hydraulic solutions in their operations, ultimately driving progress towards a more sustainable and high-performing future. Join us as we delve into the transformative possibilities that lie ahead!

In the ever-evolving landscape of industrial technology, the quest for optimal hydraulic performance has never been more critical. As we look towards the horizon of 2025, emerging trends in hydraulic solutions promise to revolutionize the way we approach fluid power systems across various sectors, from manufacturing to renewable energy. This blog will explore innovative strategies and cutting-edge technologies that enhance hydraulic efficiency, reduce energy consumption, and improve system reliability. By examining key advancements and providing actionable insights, we aim to equip industry professionals with the knowledge needed to implement effective hydraulic solutions in their operations, ultimately driving progress towards a more sustainable and high-performing future. Join us as we delve into the transformative possibilities that lie ahead!

Innovative Technologies Transforming Hydraulic Systems in China

As the demand for efficient and reliable hydraulic systems continues to grow, innovative technologies are transforming the landscape of hydraulic performance in China. Companies are increasingly adopting advanced materials and smart engineering solutions that enhance the durability and responsiveness of hydraulic components. Cutting-edge developments, such as the integration of IoT sensors and predictive maintenance algorithms, are not only optimizing operational efficiency but also reducing downtime and maintenance costs.

In addition to smart technologies, the emphasis on sustainability is driving innovation in hydraulic systems. Manufacturers are exploring eco-friendly hydraulic fluids and energy-efficient designs that minimize environmental impact while maintaining peak operational performance. The combination of these innovative approaches is paving the way for hydraulic systems that are not only robust but also aligned with global sustainability goals, making them more attractive to industries focused on reducing their carbon footprint. With these advancements, China's hydraulic sector is set to lead the way in optimal hydraulic performance on a global scale.

Innovative Technologies Transforming Hydraulic Systems in China

The following bar chart illustrates the adoption rates of various innovative technologies in hydraulic systems across different sectors in China over the past year.

Key Factors Driving China's Leadership in Hydraulic Solutions

China has emerged as a global leader in hydraulic solutions, driven by rapid industrialization and technological advancements. The market for level sensors, particularly in the hydraulic field, is expected to witness significant growth. According to recent industry reports, the global level sensor market is projected to reach approximately $4 billion by 2026, with a substantial share attributed to China. This surge can be largely linked to the increasing demand for precise liquid measurement in various sectors, including manufacturing, oil and gas, and water management.

The level sensors market is classified predominantly into contact and non-contact types, with contact sensors like float switches and capacitive sensors being widely used for their reliability and cost-effectiveness. On the other hand, non-contact technologies, such as ultrasonic and radar sensors, are gaining traction due to their ability to provide accurate readings in challenging environments. Industry analysts anticipate that the non-contact segment will experience a compound annual growth rate (CAGR) of over 8% in the coming years, reflecting a shift towards advanced technological solutions that offer enhanced performance and safety in hydraulic applications. As China's infrastructure continues to expand, these innovations will be crucial for maintaining optimal hydraulic performance across various industries.

Case Studies: Successful Hydraulic Applications from Chinese Manufacturers

Hydraulic systems are vital to numerous industrial applications, with the global hydraulic equipment market predicted to reach $55 billion by 2027, according to a recent report by Research and Markets. Chinese manufacturers have been at the forefront of innovating solutions that optimize hydraulic performance. Through strategic investments in technology and R&D, they have demonstrated remarkable advancements that not only enhance efficiency but also minimize resource consumption.

A notable example can be seen in the case of a leading Chinese hydraulic component manufacturer that implemented a closed-loop hydraulic system in their production line. This innovation resulted in a 30% reduction in energy consumption while simultaneously increasing output by 20%. Such solutions not only benefit manufacturers economically but also align with global sustainability goals, showcasing how hydraulic applications can contribute to a more eco-friendly industrial landscape. Another case study reveals that integrating smart sensors in hydraulic machinery allowed for predictive maintenance, reducing downtime by 40% and cutting maintenance costs significantly. These examples illustrate the potential for Chinese manufacturers to set benchmarks in hydraulic technology and performance.

Future Trends: Sustainability and Efficiency in Hydraulic Engineering

The hydraulic industry is witnessing a transformative phase as sustainability and efficiency become paramount in engineering practices. With the hydraulic accessories market projected to grow from $437 million in 2024 to $768 million by 2032 at a CAGR of 7.32%, the emphasis on innovative, eco-friendly technologies is critical. In particular, advancements in hydraulic diaphragm metering pumps are expected to play a significant role in various applications, including petrochemicals, food processing, and water treatment. This growth underscores a shift towards optimizing resource use and minimizing environmental impact.

As industries across the globe transition to greener practices, the development of hydraulic technologies that support this shift cannot be overstated. Initiatives like those introduced by young entrepreneurs are demonstrating how innovation can lead to more sustainable futures. For example, the use of recycled materials in construction not only helps reduce waste but also contributes to a circular economy. Looking ahead, the focus on improving hydraulic systems to enhance efficiency while ensuring sustainability represents a promising trend that will shape the future of hydraulic engineering.

Collaboration and Investment: Building a Stronger Hydraulic Industry in China

In the rapidly evolving hydraulic industry in China, collaboration and investment are pivotal for achieving optimal hydraulic performance. By fostering partnerships across various sectors—such as engineering, manufacturing, and research—industry leaders can harness diverse expertise and resources. This united approach not only accelerates innovation but also ensures that new solutions are effectively implemented in real-world applications.

Tips for successful collaboration include establishing clear communication channels among partners and prioritizing shared goals. Regular workshops and brainstorming sessions can cultivate a creative environment, where stakeholders contribute their insights and expertise. Additionally, investing in joint training programs can enhance skill sets across organizations, ensuring that teams are well-equipped to tackle the challenges in hydraulic technologies.

Moreover, strategic investment in research and development is essential for the hydraulic industry's growth. Companies should focus on funding projects that emphasize sustainable practices and advanced technologies, which can lead to groundbreaking solutions. By allocating resources to projects that align with industry demands, stakeholders can create a competitive edge that drives the hydraulic sector forward in the global market.

We have over 30 years of experience in designing complete hydraulic systems, repairs and distribution of fluid power equipment and parts.

FOLLOW US ON :

Contact Details

Address:

4020 SE 45th CT.

Ocala, FL 34480

Phone No:

Email:

sales@cunninghamfluidpower.com