Essential Checklist for Choosing the Best Hydraulic Parts for Your Industrial Needs

When it comes to maintaining the efficiency and reliability of your industrial operations, choosing the right hydraulic parts is pivotal. The hydraulic system is the heart of many machines, and ensuring that each component functions optimally can significantly affect overall performance. With a myriad of options available in the market, it can be daunting to determine which hydraulic parts are best suited for your specific industrial needs. This checklist serves as your guide to navigate through various considerations such as compatibility, materials, and supplier reputation, ensuring that you make informed decisions. By focusing on these top factors, you can enhance productivity, reduce downtime, and ultimately contribute to a more efficient operation, making your investment in hydraulic parts a success.

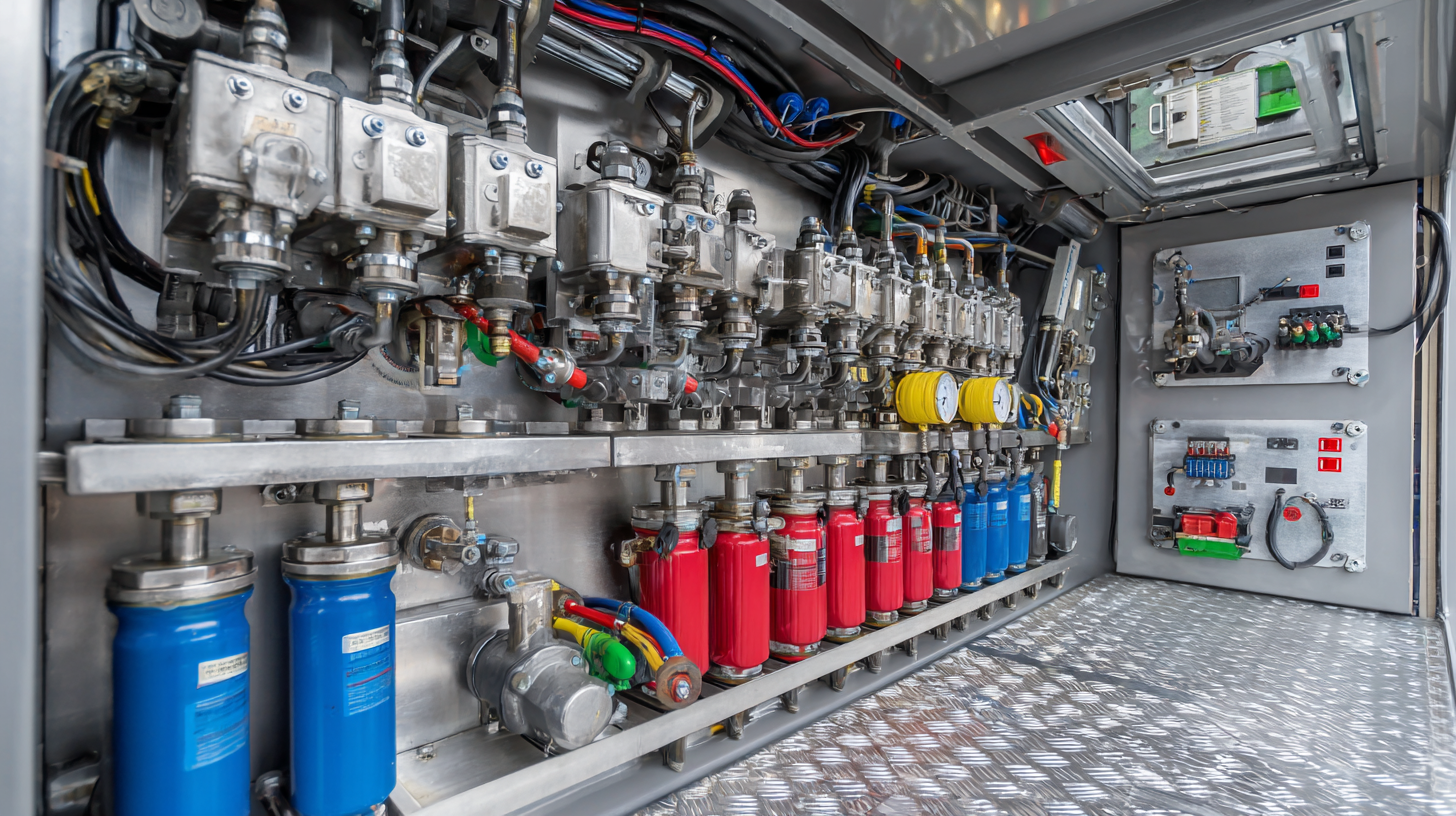

Understanding Your Hydraulic System Requirements

When selecting the best hydraulic parts for your industrial needs, understanding your hydraulic system requirements is crucial. A reliable hydraulic system is fundamental to the efficiency and effectiveness of various operations, and this starts with recognizing the specific needs of your application. Factors such as compatibility with biodegradable hydraulic fluids, which have recently seen significant advancements in formulation to enhance sustainability and performance, should be considered. These fluids can play a pivotal role in reducing environmental impact while still delivering the necessary power and efficiency required for operations.

Moreover, examining the latest advancements, such as the development of digitally controlled variable displacement piston pumps, emphasizes the importance of noise reduction and efficiency in hydraulic solutions. Additionally, with the rise of electrified hydraulic systems, particularly in electric vehicles, it’s essential to ensure that your hydraulic parts can support the growing demand for energy efficiency and reliability. Considering the overall market trends and the technological innovations available will empower you to make an informed decision that aligns with your operational goals and environmental commitments.

Essential Checklist for Choosing the Best Hydraulic Parts for Your Industrial Needs

| Component | Material | Pressure Rating (psi) | Temperature Range (°C) | Application |

|---|---|---|---|---|

| Hydraulic Pump | Cast Iron | 3000 | -20 to 80 | Construction Equipment |

| Hydraulic Hose | Rubber | 4000 | -40 to 100 | Agricultural Machinery |

| Hydraulic Cylinder | Aluminum | 5000 | -30 to 90 | Manufacturing Processes |

| Control Valve | Steel | 2500 | -20 to 80 | Automotive Industry |

| Hydraulic Filter | Polypropylene | 1500 | -20 to 70 | Oil & Gas |

Key Specifications to Consider for Hydraulic Parts

When selecting hydraulic parts for industrial applications, understanding key specifications is crucial for performance and reliability. First, consider the pressure rating of the components. Different hydraulic systems operate under varying pressure levels, so it’s essential to choose parts that can withstand the maximum pressure your system will encounter. Look for components rated above your system’s maximum pressure to ensure safety and durability.

Another critical specification is the flow rate. This measurement indicates how much fluid can move through the system and affects the efficiency of machinery. Ensure that the hydraulic parts you select can handle the required flow rate for optimal performance. Additionally, pay attention to the material compatibility and seals used in the hydraulic components. Choosing the right materials will prevent leaks and ensure that your parts can withstand the operating environment, whether that involves exposure to chemicals, high temperatures, or abrasive materials. By focusing on these specifications, you can ensure that your hydraulic system operates smoothly and effectively.

Evaluating Quality and Durability of Hydraulic Components

When it comes to selecting hydraulic components for industrial applications, evaluating their quality and durability is paramount. The reliability of these parts directly impacts the performance and safety of systems, especially in a rapidly growing market, such as the global automotive hydraulic system sector, projected to expand from $47.43 billion in 2023 to $57.80 billion by 2030. A careful selection process can significantly influence operational efficiency and long-term maintenance costs, making it essential to prioritize quality over price.

To ensure the longevity of hydraulic components, look for products constructed from high-quality materials that can endure harsh operating conditions. Factors such as resistance to corrosion, wear, and temperature fluctuations are critical to assessing a part's durability. Additionally, consider the manufacturer's reputation and whether they adhere to industry standards and certifications. Investing time in these evaluations not only enhances performance but also supports sustainable practices in heavy industries, ultimately leading to more reliable hydraulic systems and improved productivity across operations.

Selecting the Right Manufacturer for Hydraulic Parts

When selecting the right manufacturer for hydraulic parts, it's crucial to consider several key factors that directly impact your operations. First and foremost, research the manufacturer's reputation within the industry. Look for reviews and testimonials from previous clients to gauge their reliability and quality. A well-established manufacturer is often backed by years of experience, ensuring that their products meet the required standards and specifications.

Tip: Request samples or visit the manufacturing facility to observe the production processes. This firsthand experience can reveal a lot about the quality and precision of their hydraulic components.

Another important aspect is the range of products offered by the manufacturer. Partnering with a company that provides a wide selection of hydraulic parts ensures that all your needs can be met under one roof, simplifying your supply chain management. Additionally, strong after-sales support should not be overlooked; a manufacturer who provides comprehensive support can help you address any issues that may arise post-purchase.

Tip: Establish a relationship with the manufacturer to facilitate better communication. A collaborative approach often leads to better customization options and quicker resolutions to technical challenges.

Cost-Benefit Analysis: Balancing Price and Performance

When selecting hydraulic parts for industrial applications, a thorough cost-benefit analysis is essential to strike the right balance between price and performance. According to a recent report by MarketsandMarkets, the hydraulic equipment market is projected to grow from $41.38 billion in 2021 to $57.31 billion by 2026, indicating a robust demand that often leads to competitive pricing. However, choosing cheaper components can result in long-term costs due to lower durability and higher maintenance needs. Therefore, investing in high-quality hydraulic parts can significantly enhance operational efficiency while reducing downtime and replacement frequency.

Performance is equally critical; the right hydraulic parts not only ensure optimal functionality but also contribute to energy efficiency. The International Energy Agency (IEA) notes that improving the efficiency of hydraulic systems can lead to energy savings of up to 30%. These savings often outweigh the initial investment costs when high-performance components are utilized. By comparing the total cost of ownership against the expected performance improvements, industrial operators can make informed choices that enhance productivity while ensuring cost-effectiveness in their operations.

We have over 30 years of experience in designing complete hydraulic systems, repairs and distribution of fluid power equipment and parts.

FOLLOW US ON :

Contact Details

Address:

4020 SE 45th CT.

Ocala, FL 34480

Phone No:

Email:

sales@cunninghamfluidpower.com