How to Choose the Best Hydraulic Valves for Your Industrial Applications

In the rapidly evolving landscape of industrial automation, selecting the right hydraulic valves is integral to ensuring the efficiency and reliability of hydraulic systems. According to a recent market report by Grand View Research, the global hydraulic valve market is expected to reach $42.4 billion by 2025, driven by the increasing demand for advanced hydraulic systems across various industries including manufacturing, construction, and agriculture.

This surge in market growth underscores the necessity for businesses to carefully evaluate their hydraulic valve options, taking into account factors such as flow capacity, pressure ratings, and compatibility with existing systems. As industries push for higher productivity and sustainability, understanding the intricacies of hydraulic valves will not only enhance operational performance but also contribute to cost savings and improved safety standards.

Understanding the Basics of Hydraulic Valves and Their Functions

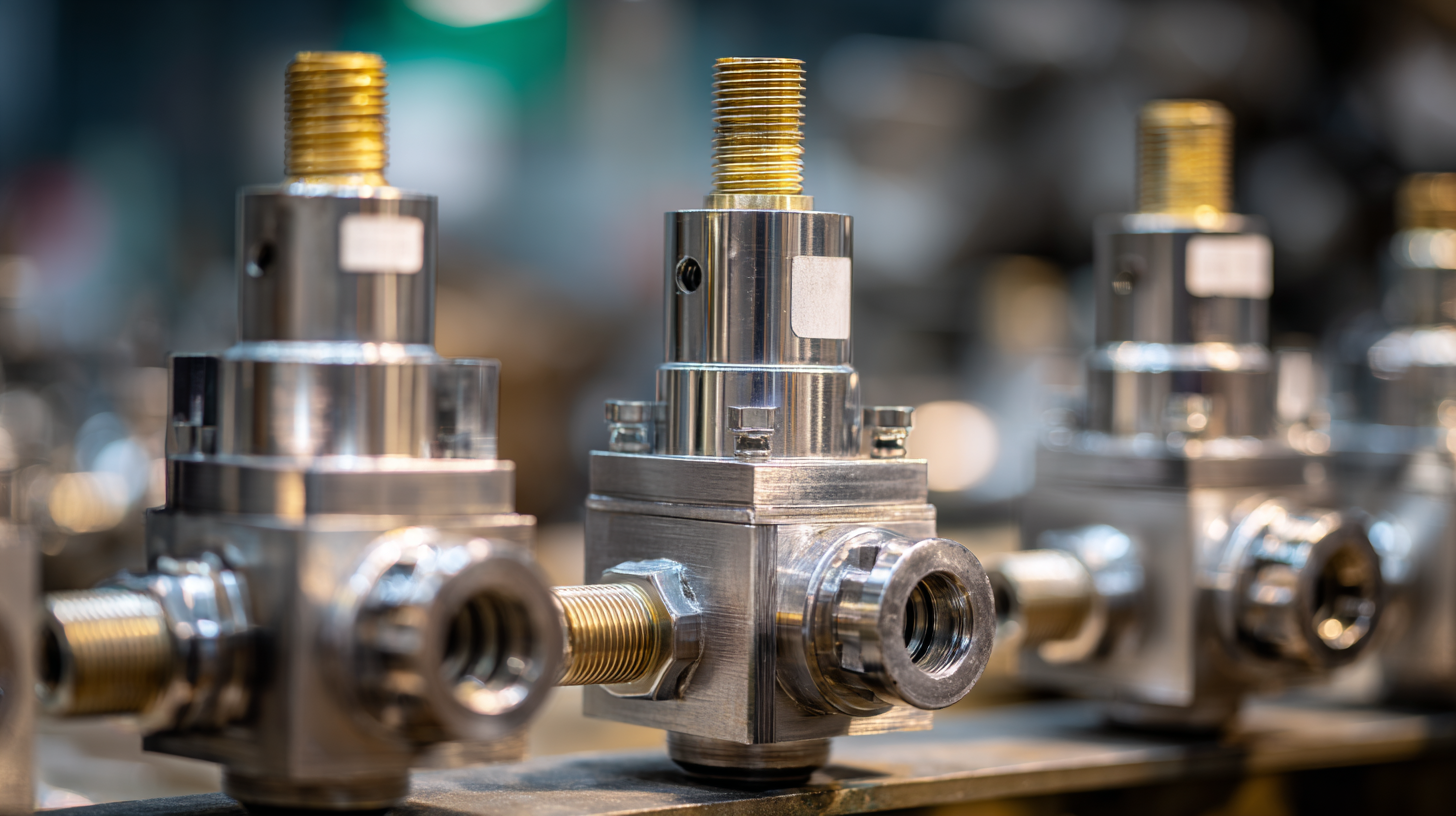

Hydraulic valves are essential components in a hydraulic system, regulating fluid flow and pressure to ensure optimal operation. Understanding the basics of hydraulic valves involves grasping their types, functions, and applications. There are several types of hydraulic valves, including directional control valves, pressure control valves, and flow control valves, each serving a distinct purpose. Directional control valves manage the path of hydraulic fluid, allowing operators to control the movement of actuators. Pressure control valves safeguard the system by regulating pressure levels, preventing potential damage or failure.

Another critical aspect of hydraulic valves is their functionality within various industrial applications. These valves can be found in manufacturing, construction, agriculture, and more, playing a pivotal role in machinery operations. For instance, flow control valves are used in systems where precise motion is necessary, such as in robotic arms or conveyor belts. Understanding these basic functions enables engineers and operators to select the right valves for their specific needs, ensuring efficiency and reliability in their hydraulic systems. Proper selection and maintenance of hydraulic valves can significantly enhance system performance and prolong equipment lifespan.

Exploring Different Types of Hydraulic Valves and Their Applications

When it comes to hydraulic systems, selecting the right valve is crucial for optimal performance. There are several types of hydraulic valves, each designed for specific applications. Directional control valves are commonly used to manage the flow direction of hydraulic fluid. They come in various configurations, including two-way and four-way valves, and are essential for controlling cylinders and motors in industrial machinery.

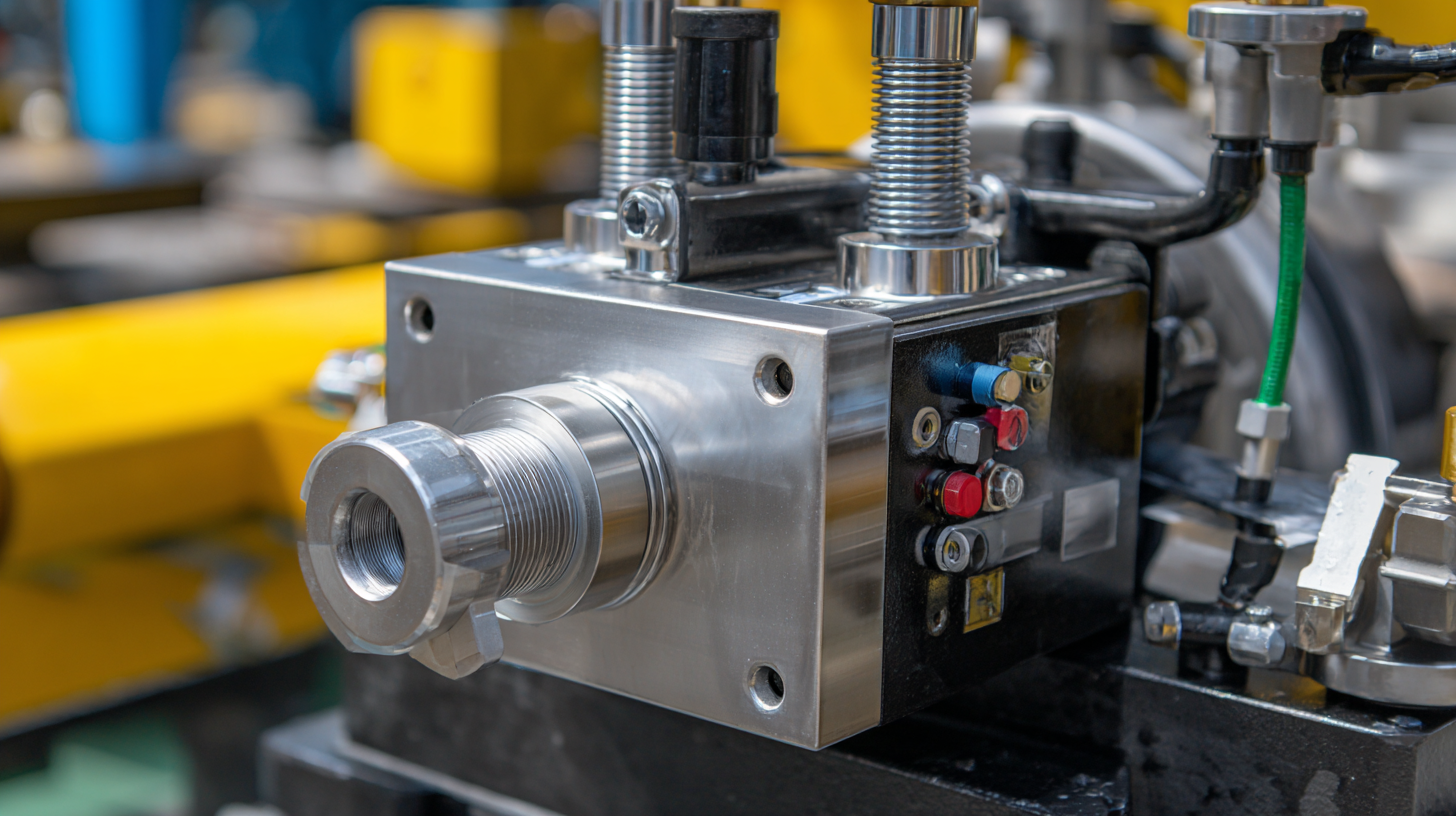

Pressure control valves, on the other hand, play a vital role in maintaining safe operating levels within hydraulic systems. These valves, including pressure relief and pressure reducing valves, prevent over-pressurization and ensure that equipment runs smoothly. In applications where flow regulation is necessary, flow control valves allow for precise adjustments to fluid flow rates, enhancing the efficiency of hydraulic operations. Understanding the specific requirements of your industrial application is key to choosing the right hydraulic valve, ensuring reliability and effectiveness in your system.

Factors to Consider When Choosing Hydraulic Valves for Specific Industries

When selecting hydraulic valves for specific industries, several critical factors must be considered to ensure optimal performance and reliability. The first factor is the operational environment. For instance, valves used in the oil and gas sector, which can experience extreme pressures and corrosive substances, must meet stringent standards such as API 6A. According to a 2021 report by the Global Hydraulic Valve Market, approximately 30% of hydraulic failures in industrial applications are attributed to inadequate valve selection for environmental conditions.

Another vital consideration is flow rate and pressure requirements. Industries like automotive manufacturing typically require high-speed operation and precise flow control. Research from the International Hydraulic Association suggests that properly sized hydraulic valves can improve system efficiency by up to 20%. Furthermore, compatibility with other hydraulic components is crucial; mismatched parts can lead to poor performance and increased maintenance costs. Ultimately, understanding the specific needs of your application and aligning them with industry standards and data-driven insights is essential for choosing the right hydraulic valves.

Common Mistakes to Avoid When Selecting Hydraulic Valves

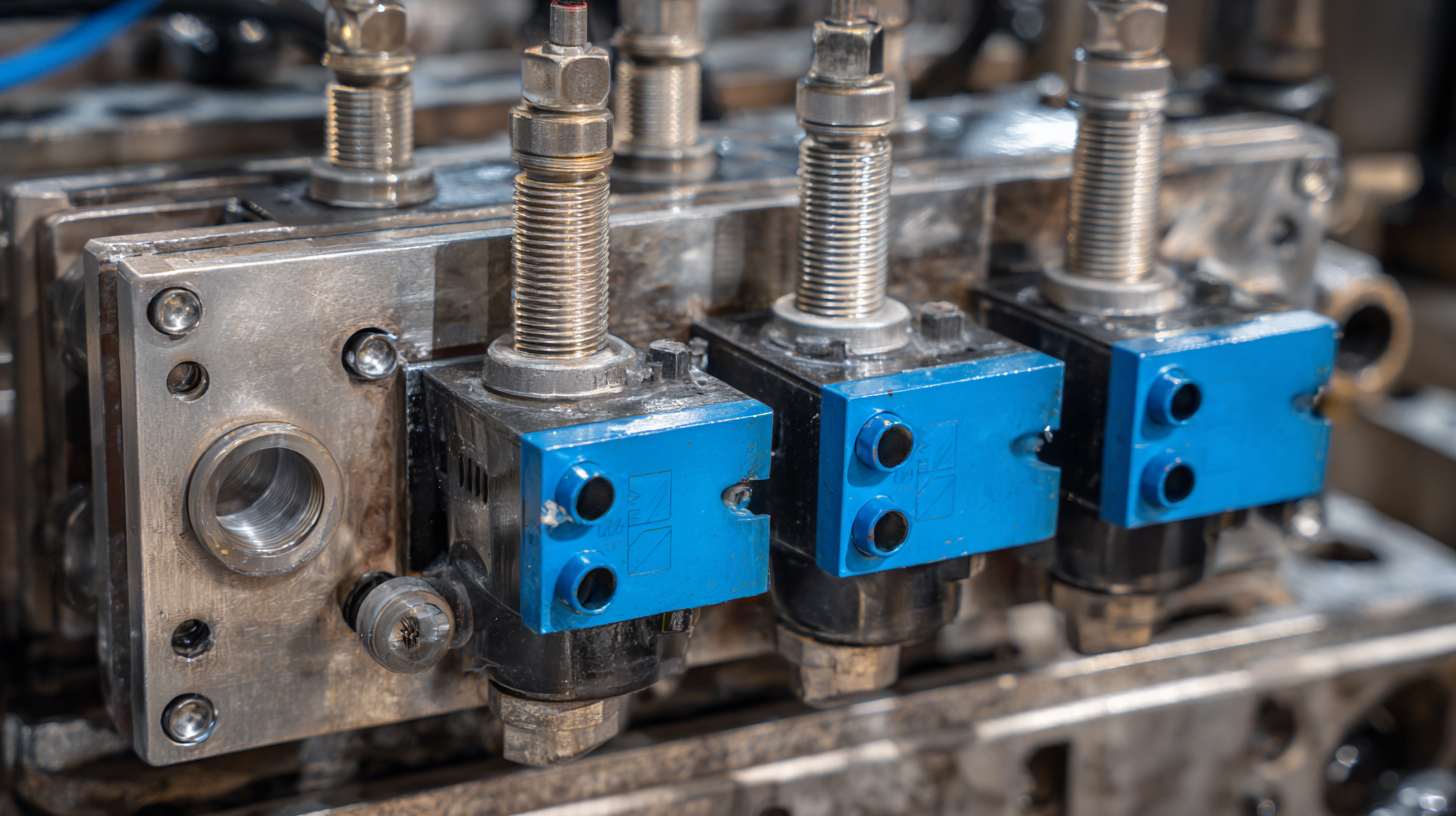

When selecting hydraulic valves for your industrial applications, avoiding common mistakes can save time and resources. One of the most frequent errors is overlooking the specifications required for your specific operation. Each hydraulic system has unique demands, such as pressure ratings, flow requirements, and fluid compatibility. Failing to match these specifications can lead to valve malfunction or system failure, ultimately causing costly downtime.

Another mistake to steer clear of is neglecting to consider the environmental conditions in which the hydraulic valves will operate. Factors such as temperature variations, exposure to moisture or corrosive substances, and vibration levels can significantly impact a valve's performance. Choosing valves that are not designed for harsh environments can result in premature wear and failure, leading to increased maintenance costs and operational inefficiencies. Always evaluate the operational setting to ensure proper valve selection that can withstand the specific conditions encountered in your industry.

Hydraulic Valve Selection Mistakes

Maintenance Tips for Ensuring Optimal Performance of Hydraulic Valves

Hydraulic valves are critical components in hydraulic fluid power systems, playing an essential role in various industrial applications such as transportation, heavy machinery, and robotics. To ensure the optimal performance of these valves and to extend their lifespan, regular maintenance is crucial.

One key maintenance tip is to frequently check for leaks and ensure that seals are intact. A small leak can lead to significant efficiency losses and potential system failures. Additionally, regular cleaning of the valves helps remove any contaminants that could cause wear or blockages.

Another important practice is to monitor the hydraulic fluid quality. Utilizing filters and ensuring proper fluid levels can prevent the degradation of valve components. Establishing a schedule for systematic inspections and maintenance tasks will help identify potential issues early, ultimately enhancing the performance and reliability of hydraulic systems.

We have over 30 years of experience in designing complete hydraulic systems, repairs and distribution of fluid power equipment and parts.

FOLLOW US ON :

Contact Details

Address:

4020 SE 45th CT.

Ocala, FL 34480

Phone No:

Email:

sales@cunninghamfluidpower.com