Unlocking Global Supply Chains How to Identify Top Suppliers for Best Hydraulic Parts

In today's interconnected world, the importance of optimizing global supply chains cannot be overstated, especially when it comes to sourcing high-quality hydraulic parts. As industries increasingly rely on advanced hydraulic systems for efficiency and performance, the demand for reliable suppliers has surged. However, identifying the best hydraulic parts suppliers poses a significant challenge for businesses looking to maintain operational excellence.

This blog will delve into effective strategies for unlocking supply chain potential, providing insights into how to evaluate potential suppliers based on quality, reliability, and innovative capabilities. By focusing on the right criteria, companies can forge partnerships with top suppliers that not only meet their hydraulic parts needs but also enhance their overall productivity and competitiveness in the market.

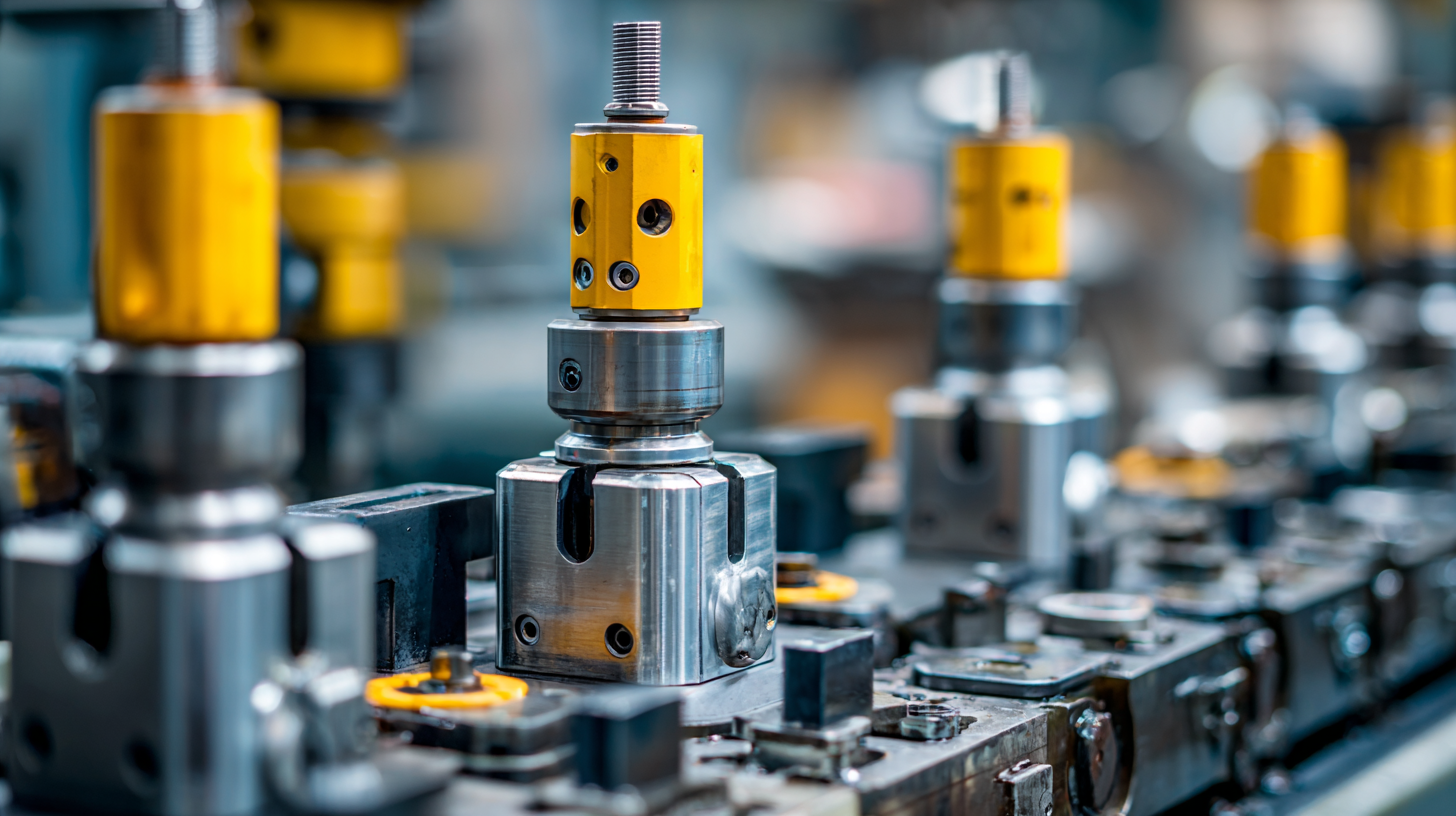

Characteristics of Hydraulic Parts Types and Their Applications

Hydraulic parts play a crucial role in various industrial applications, from construction machinery to automotive systems. Understanding the different types of hydraulic components is essential for anyone looking to maximize efficiency and reliability in their operations. Key components include hydraulic pumps, cylinders, valves, and hoses, each serving a specific function within the hydraulic system. For instance, hydraulic pumps convert mechanical energy into hydraulic energy, driving the system forward, while hydraulic cylinders facilitate the conversion of hydraulic energy back into mechanical energy to perform work.

The applications of these hydraulic parts are vast and diverse, ranging from heavy-duty construction equipment to precision agricultural machinery. In construction, hydraulic cylinders are indispensable for equipment like excavators and cranes, allowing for powerful lifting and digging capabilities. In agriculture, hydraulic valves regulate the flow of fluids to various implements, enhancing adaptability and functionality. As industries evolve, understanding the characteristics and applications of these hydraulic components becomes more critical. This knowledge enables companies to select the right suppliers and ensure that their hydraulic systems operate effectively and efficiently, driving productivity and reducing downtime.

Key Criteria for Evaluating Top Suppliers in Hydraulic Components

When searching for top suppliers of hydraulic components, it's crucial to establish key criteria that can guide your evaluation process. First and foremost, assess the supplier's industry experience and reputation. Suppliers with a long-standing presence in the market often have proven records of reliability and quality. Look for testimonials or case studies that highlight their expertise in producing specific hydraulic parts. Additionally, certifications such as ISO standards can indicate a commitment to maintaining high-quality manufacturing processes.

Another essential criterion is the supplier’s technical capabilities. Evaluate their range of products and the technologies they employ, as these factors can significantly influence the performance and longevity of hydraulic systems. It's also beneficial to consider their ability to offer customized solutions tailored to your unique requirements. Finally, take into account their logistical capabilities, including lead times and delivery options. A supplier who can meet your deadlines consistently can be invaluable in maintaining the flow of your operations and minimizing downtime.

By focusing on these criteria, you can uncover suppliers that not only meet your needs but also enhance your overall supply chain efficiency.

Understanding the Role of Quality Standards in Hydraulic Parts Supply

When assessing the importance of quality standards in the supply of hydraulic parts, it becomes clear that these standards are not just regulatory hurdles; they are crucial for ensuring reliability and safety across various applications. The hydraulic components used in machinery, from cranes to mobile vehicles, must consistently meet strict quality benchmarks to avoid failures that can lead to costly downtimes or dangerous accidents. As industries evolve—such as the rise of electric vehicles and advances in aviation technology—the need for high-quality hydraulic solutions remains fundamentally important.

In the current market landscape, suppliers that prioritize adherence to recognized quality standards distinguish themselves as reliable partners. Many effective suppliers utilize certifications and comply with industry regulations to showcase their commitment to quality. For instance, the increasing competition from manufacturers seeking to enter global markets highlights the necessity of maintaining rigorous quality checks to satisfy international procurement criteria. As buyers navigate their options, focusing on suppliers who demonstrate a commitment to quality assurance in hydraulic parts will help ensure a stable and efficient supply chain.

Navigating the dynamic landscape of hydraulic parts supply requires a keen understanding of how quality standards underpin supplier reliability. Industry players must remain vigilant, leveraging tools such as supplier directories and accreditation filters to identify top-tier suppliers that uphold stringent quality measures. In doing so, companies can harness the full potential of their hydraulic systems and drive operational excellence.

Emerging Trends in Global Supply Chains for Hydraulic Components

The global supply chain for hydraulic components is evolving rapidly, fueled by burgeoning markets and technological advancements. The hydraulic cylinder market, valued at USD 14.3 billion in 2021, is expected to reach USD 18.3 billion by 2027. This growth is indicative of the increasing reliance on hydraulic systems across various industries, such as construction and automotive, where efficiency and power are paramount. Emerging trends like the integration of 5G technology and Generative AI into supply chain operations are poised to enhance connectivity and efficiency, providing a platform for real-time data sharing and predictive analytics.

Moreover, the shift toward sustainable practices in energy and supply chain management is redefining supplier relationships. As energy storage technologies advance, their role in facilitating the decarbonization of global energy systems becomes increasingly significant. Suppliers that prioritize sustainability not only comply with regulations but also attract eco-conscious customers, setting the stage for robust business opportunities. In this dynamic landscape, identifying top suppliers who are adaptable and forward-thinking is essential for businesses aiming to streamline operations and stay competitive in an ever-changing market.

Unlocking Global Supply Chains: How to Identify Top Suppliers for Best Hydraulic Parts

| Supplier Location | Component Type | Quality Certification | Lead Time (Weeks) | Annual Production Capacity | Sustainability Practices |

|---|---|---|---|---|---|

| Germany | Hydraulic Pumps | ISO 9001 | 6 | 50000 units | Recycling Programs |

| USA | Hydraulic Cylinders | ISO 14001 | 4 | 75000 units | Energy Efficiency |

| China | Hydraulic Valves | CE Mark | 8 | 100000 units | Waste Reduction |

| Italy | Hydraulic Hoses | ISO 45001 | 5 | 60000 units | Eco-Friendly Materials |

Managing Risks in Sourcing Hydraulic Parts from Various Suppliers

Sourcing hydraulic parts from various suppliers can significantly reduce operational risks, but it also introduces a range of potential challenges. According to a recent report by MarketsandMarkets, the global hydraulic components market is projected to reach USD 66.9 billion by 2026, indicating a robust demand for quality suppliers. However, with this increased demand comes the necessity for rigorous supplier assessment to mitigate risks associated with subpar quality and logistical delays.

One key strategy in managing these risks is to conduct thorough due diligence on potential suppliers. This includes evaluating their production capabilities, quality control processes, and financial stability. Industry experts recommend visiting supplier facilities whenever possible, as this can provide insights that are often not apparent through documentation alone.

**Tips:** Always request and review certifications such as ISO 9001 to ensure adherence to international quality standards. Additionally, consider diversifying your supplier base to avoid reliance on a single source, which can help safeguard against disruptions. Utilizing technology for real-time tracking and forecasting can also enhance supply chain resilience, enabling quick responses to any unforeseen challenges.

Top Suppliers for Hydraulic Parts

This chart illustrates the reliability scores of various suppliers in the hydraulic parts industry, which is essential for managing risks in sourcing. The scores are based on quality, delivery time, and price competitiveness.

We have over 30 years of experience in designing complete hydraulic systems, repairs and distribution of fluid power equipment and parts.

FOLLOW US ON :

Contact Details

Address:

4020 SE 45th CT.

Ocala, FL 34480

Phone No:

Email:

sales@cunninghamfluidpower.com